The global supply chain is continually evolving to keep up with the current era's frenetic technical breakthroughs. Though it might be challenging for supply chain managers and business leaders to keep up with these developments, it is critical to do so in order to preserve supply chain resilience and boost your company's performance.

Supply Chain Management (SCM) spans a wide variety of tasks and necessitates meticulous attention to detail. As a result, most enterprise resource planning software includes SCM-specific modules and functionalities. Managers may use the software to improve supply chains, keep them operating as smoothly as possible, and avoid disruptions that harm customer service.

As a result, novel techniques to handle them more efficiently and effectively, as well as to increase resilience in supply chain operations, are required.

We will witness a rise in the deployment of digital supply chain technology, as well as technologies that assist human decision making, during the next three to five years.

Rise in supply chain technologies

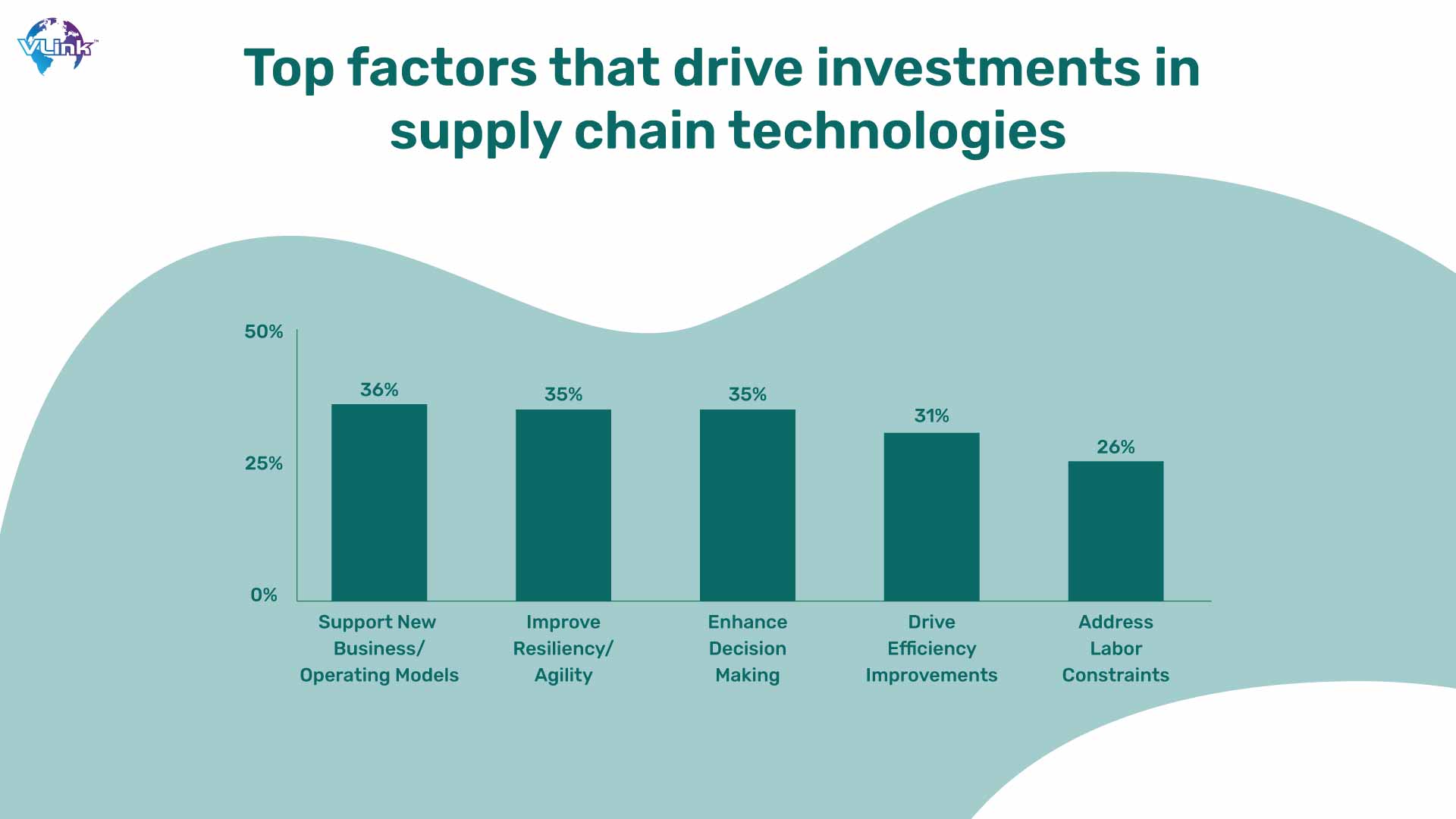

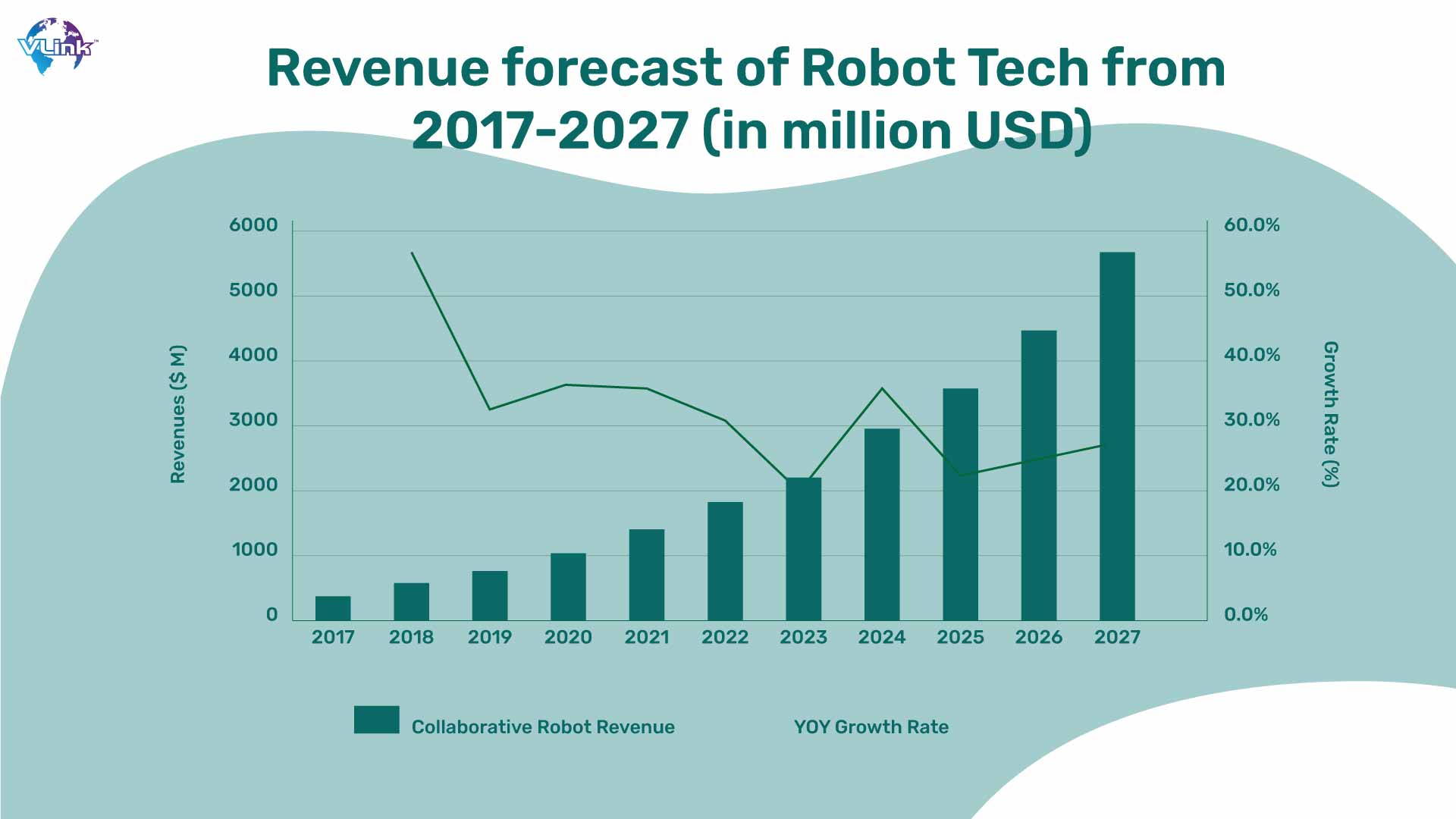

For supply chain firms, technology is a strategic requirement. Recent surveys from Gartner found that 61% of respondents see advanced technologies as key differentiators for being competitive. Several developing technologies are also identified as significant investment areas by many, with 20% investing in robots.

75% of big firms will deploy intralogistics smart robots in their warehouse operations by 2026.

These robots are designed to assist human labor by automating some operations. Implementation is quicker and less expensive than more standard automation methods such as conveyor sortation or automated guided vehicles.

Technology adoption and deployment in supply chain operations vary substantially per technology. Cloud computing is the most widely used technology (84%), followed by the Internet of Things (IoT) (79%).

Although technologies like scan and intelligent data collection, as well as third-party expenditure analytics tools, were not far behind, fewer than half of respondents said their organizations had completely or partially embraced drones, augmented reality, robotics, or robotic process automation.

Rather than trailing change, it is preferable to keep ahead of supply chain management (SCM) trends that are influencing the future of SCM. Let’s begin with the top supply chain technology trends that will shape the industry in the future:

10 emerging supply chain technology trends

In several industries, the usage of artificial intelligence (AI) and automation is increasing. Automation, which has existed for decades, uses technology to reduce human inputs and is basically a machine completing a series of activities.

There are several methods to apply AI and automation into your organization's workflow, ranging from improving your manufacturing line to powering digital twin technologies and everything in between.

AI-integrated software solutions have a wide range compatibility feature with multiple functions such as intelligent sourcing, inventory management, and even logistical routes in supply chain management. AI may also be used to track future supply chains or automate supply chains.

Deloitte estimated "79% of companies with high-performing supply chains achieve revenue growth that exceeds the industry average, while businesses with optimized supply chains have 15% lower supply chain costs, less than 50% inventory holdings, and 3X faster cash to cash cycles."

With social distancing and remote labor, digital has surpassed manual since it gives real-time data from across the supply chain as well as exact analytics. This helped to avoid several interruptions. They reconstruct a full supply chain and its procedures in a digital environment that is easily accessible.

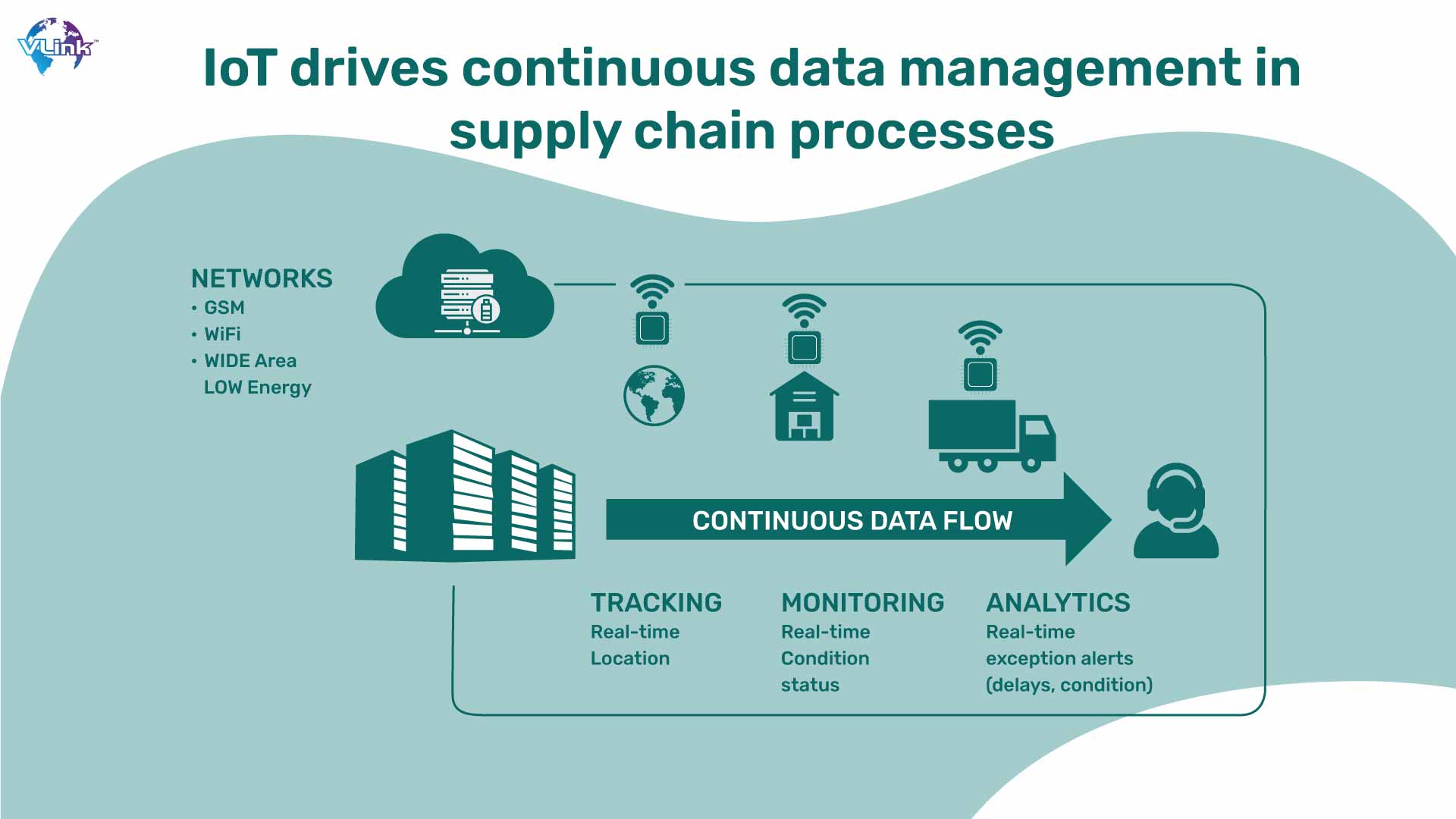

Real-time data from IoT devices provides complete insight into everything, from consumer orders to specific commodities moving through the supply chain. It can detect production delays and their implications, as well as alert you to machinery that needs to be repaired.

They provide substantial benefits to sectors outside of supply chain management as well but need a significant financial and equipment commitment.

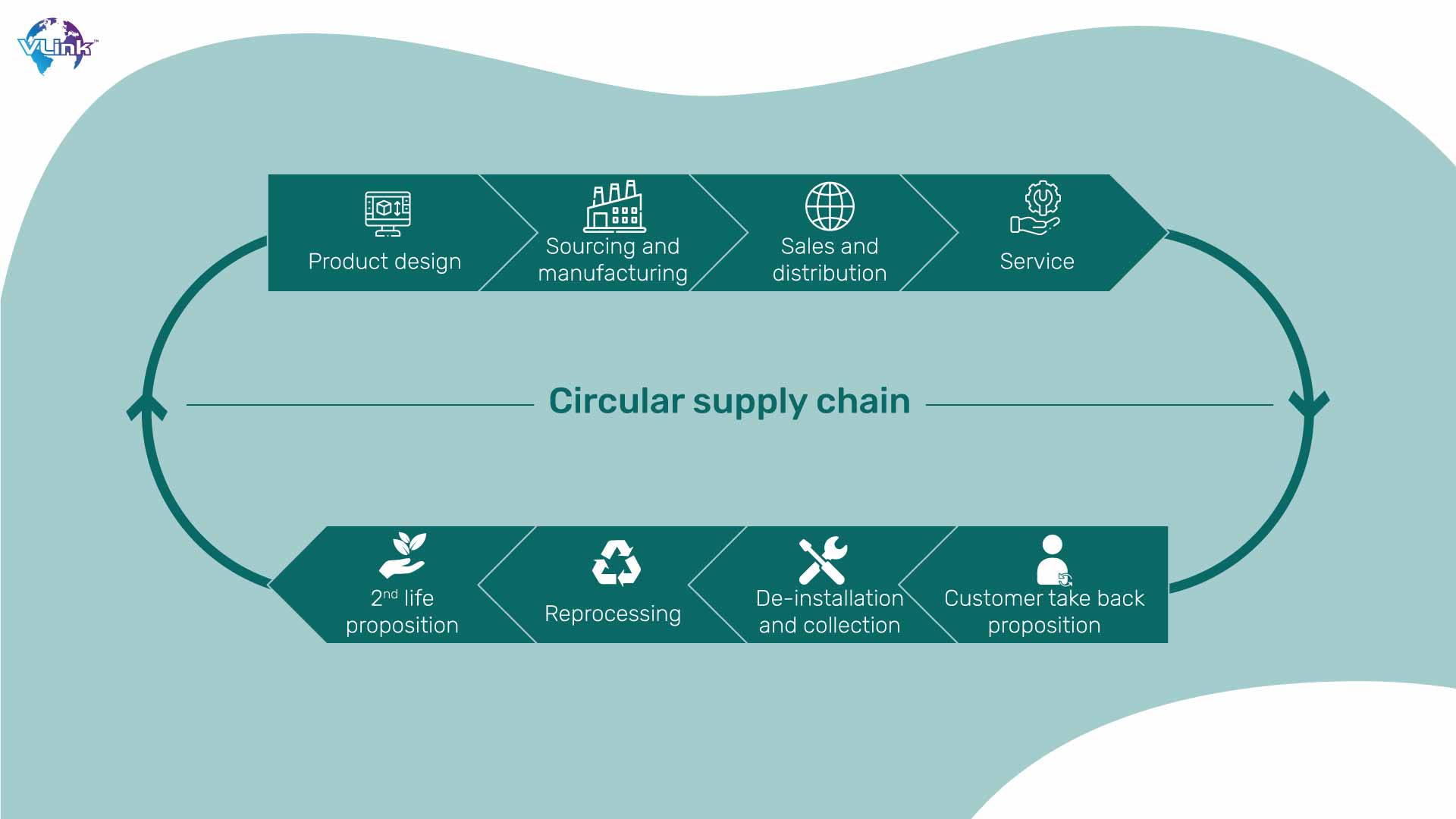

Sustainability has become one of the most crucial factors for the success of supply chain management businesses. Previously, linear supply chains caused waste by discarding unused components after producing a product.

Circular supply chains recycle unwanted pieces back into their value chains rather than generating an item and returning to the beginning of the chain with brand new resources. To summarize, circular supply networks encourage a zero-waste environment.

Customers care about the ethics of the things they purchase. Frequently demanding specifics on how, with what, and where production takes place. Governments frequently set rules that limit trash and encourage reclamation, so consumers aren't the only factors here.

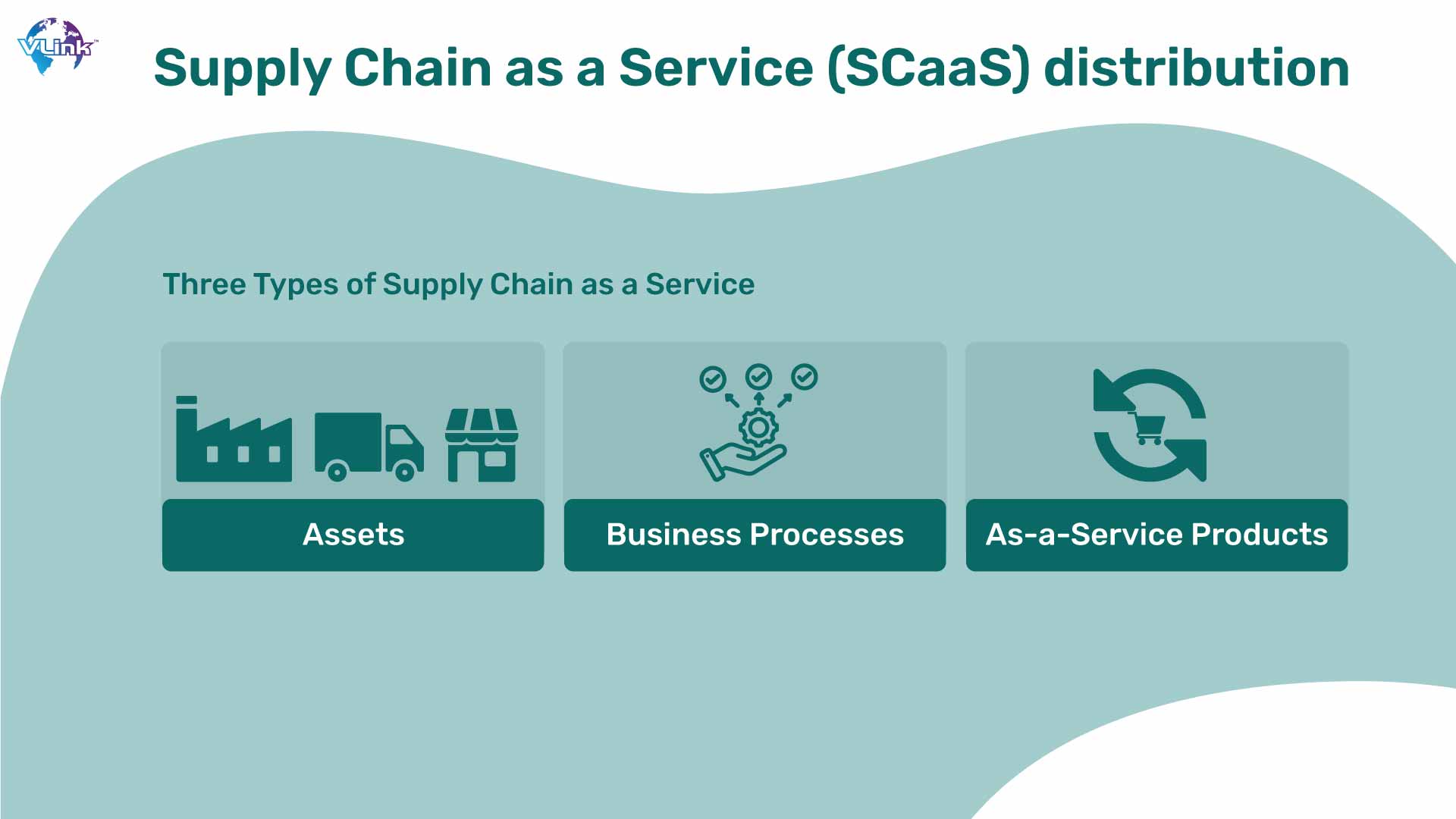

Most of the SCM operations are still under the vision of in-house staff people. Nonetheless, we may see more organizations embrace 'Supply Chain as a Service' (SCaaS) business models and outsource tasks such as manufacturing, shipping, and inventory management.

Companies' supply chain management teams will eventually transform into a smaller number of qualified employees focused on making strategic supply chain choices. Control towers will become increasingly common as in-house supply chain teams shrink (Forbes, 2019). These modern digital control towers provide supply chain managers with a complete picture of the supply chain.

Similarly, technological advancements have improved SCM support. This strategy, first seen in SaaS software, allows businesses to cut overhead spending by eliminating fixed expenses in infrastructure, updates, and maintenance.

With the rising popularity of blockchain, it makes sense to follow the need for more supply chain visibility. The database structure of blockchain can help supply chains succeed by providing end-to-end transparency. Before we go any further, what precisely is blockchain?

Blockchain makes use of "blocks" of data, whereas traditional databases store information in tables. As data pours in, new blocks are generated and linked to their predecessors as these storage blocks reach their limitations.

With accurate time stamps, these blocks constitute immutable records that provide users with vital insight into all of their transactions. Blockchain allows for enhanced material tracking from the source to the client via the supply chain. Technology reduces down paperwork and administrative processes while boosting transactional security.

Intralogistics robots greatly increase warehouse automation and efficiency, resulting in speedier operations and the capacity to handle demand surges considerably better. Intralogistics robots are devices that can be operated autonomously, reprogrammed, multi-purposed (capable of being converted to a new use with physical modification), and programmable in three or more axes.

Because they can operate on restricted floor space and reach into shelves, palletizing machines, or conveyors to load and unload items, they are especially intended for intralogistics picking and putting.

The Internet of Things — the simplified connecting of multiple gadgets — improves visibility and connectivity while lowering expenses. Connect devices like smart watches, sensing tools and other wearables can play a major role in benefiting the warehouse environments.

Wearables, in particular, provide solutions that lead to a "touchless" supply chain: the complete removal of the labor-intensive process of selecting things from inventory to fulfill a client request, often known as "picking." Other IoTs enable warehouse and logistics managers to track goods and monitor equipment in a secure manner.

Many firms will also harness the power of IoT by connecting it with essential business tools like business analytics software. These interfaces will enable analytics for IoT device data, allowing businesses to make data-driven choices on supply chain strategy.

Also Read: Supply Chain Digitization: What, Why & How to do it?

Cloud systems provide comparable functionality and security to on-premises versions while avoiding sunk costs and customization issues that beset traditional software.

The cloud SCM market is predicted to expand through 2022. According to a new Markets and Markets analysis, the cloud-based supply chain management industry will be worth roughly $45.2 billion by 2027.

Many opponents of cloud-based software in the past were concerned about an outside entity accessing their program, especially with total control over uptime and security. However, as cloud-based solutions become more widespread, providers strive to be dependable and trustworthy corporate partners.

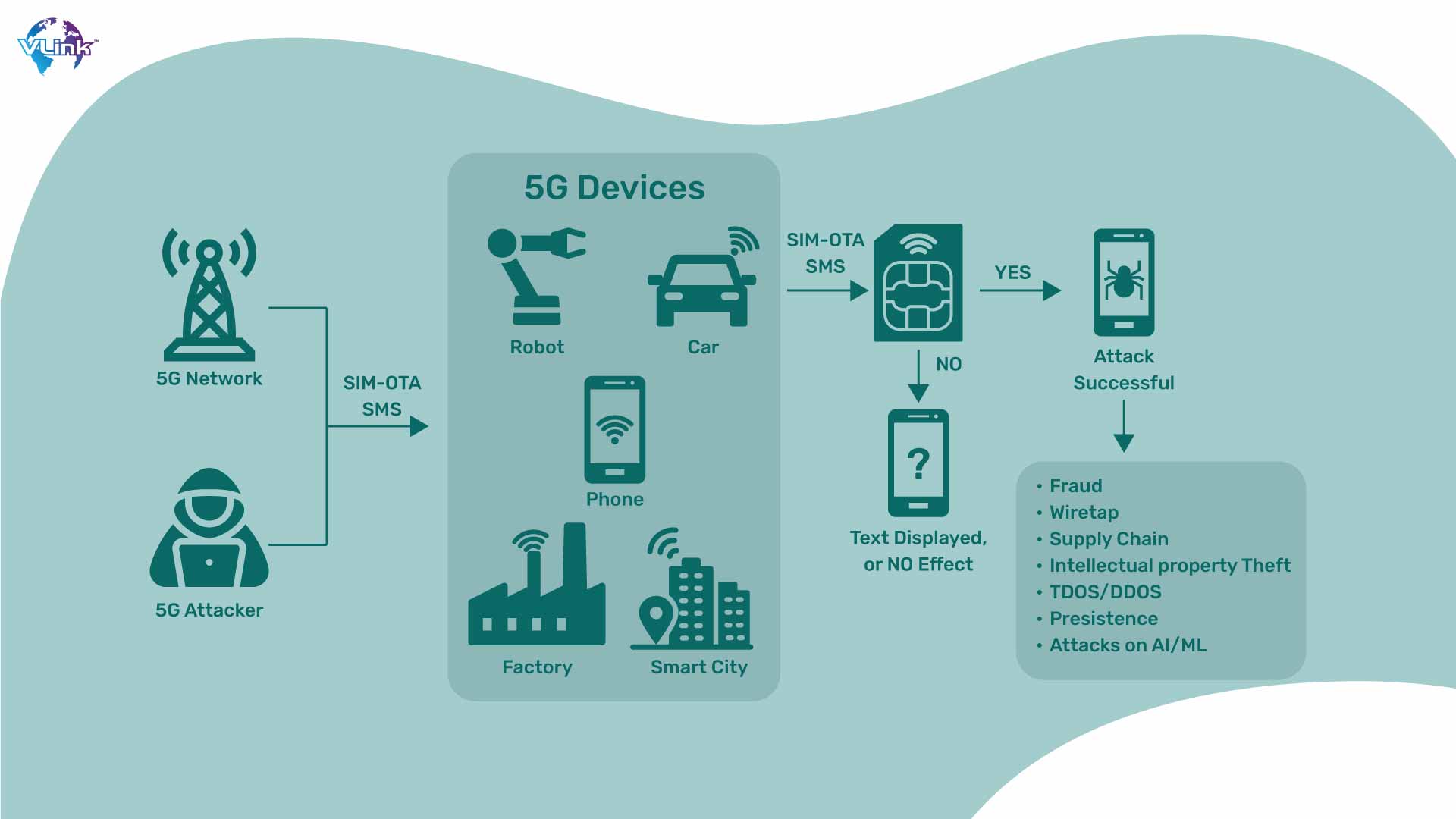

How will the future of supply chain management be affected by the arrival of 5G networks on the global stage? With IoT-enabled gadgets flooding the market, networks capable of handling massive numbers of devices are required.

The transformation of networking from 4G to 5G is impressive as it is resulting in fruitful impacts across industries. 4G networks can accommodate 10,000 devices per square mile, whereas 5G networks can support 100 times that number.

With digital transformations becoming more common, a robust network is required to guarantee that communication between processes, machines, and people is swift and smooth. 5G improves quality and optimizes critical parts of the supply chain, such as logistics, distribution, and warehouse management.

Depending on the linear approach for process management might not be enough to stay updated. Supply chain businesses should be adaptive to new innovations for tackling market changes. And that’s where elastic logistics comes to play major role.

Elastic logistics enable the supply chain to rapidly grow or contract in response to market needs. Many factors in the supply chain, including sailing timetables, carrier space, container utilization, and route optimization, benefit from elastic logistics.

The flexibility enables businesses to better manage possible difficulties like overstocking and underutilized vessel capacity. Therefore, firms may benefit from increased stability and stay competitive in the face of market swings.

How VLink can help to integrate supply chain technologies

Deploying the latest supply chain tech trends and staying ahead in the industry can guarantee the least impact on your company from several challenges. It is never too early to be ready to withstand the consequences of factors such as global trade challenges, manpower shortages, and other unforeseen occurrences like as the COVID-19 pandemic.

And that’s where VLink’s supply chain software solutions come to play a major role. Our cloud-based, comprehensive, and economical services can help you drive your supply chain business more effectively, save money, and increase sales. It is a scalable and adaptable technology that will enhance your company operations from start to finish.

Frequently Asked Questions

For optimum efficiency, the supply chain transformation approach focuses on integrating the supply chain with your broader company goals. It’s less about material flows and more about shifting roles inside the company, which necessitates a step-by-step, strategic approach.

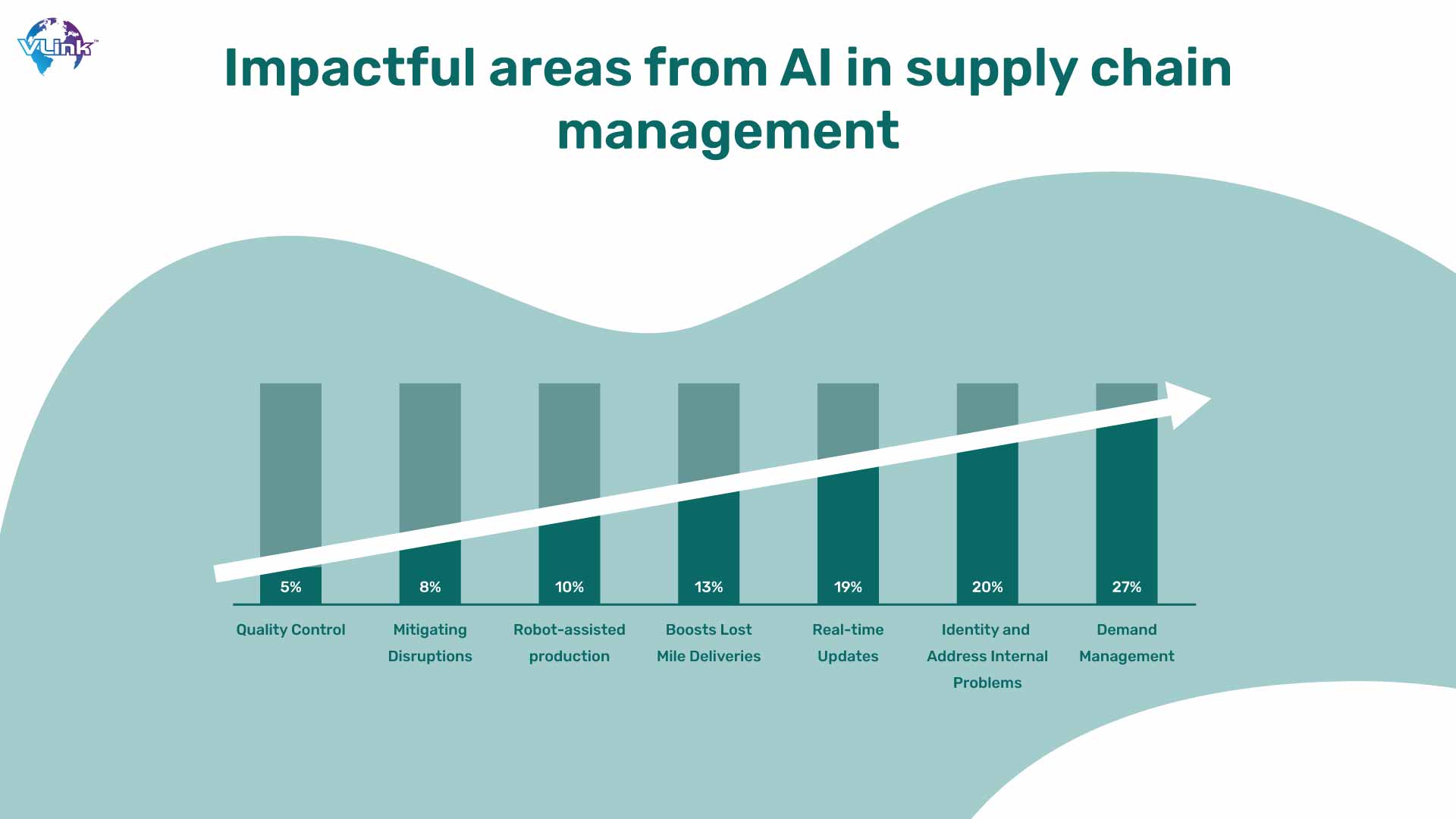

Artificial intelligence (AI) integrations can smoothen the analysis and monitoring of large volume of data, discovering trends and generating predictions about future issues. AI systems are quick, efficient, and never-ending, allowing them to increase supply chain efficiency, minimize the need for human labor, improve safety, and save costs.

In this digital era, there are several innovations that are transforming industries with their ever-evolving capabilities. Supply chain businesses can also leverage them to escalate growth, ease processes, boost productivity, and attain utmost efficiency. The topmost technologies are AI, IoT, robotics, automation, blockchain, cloud and 5G networking.